Unlocking the Power of PDCA: A Step-by-Step Guide to Continuous Improvement

Umang Chauhan

Aug 28, 2024

Introduction

The Plan-Do-Check-Act (PDCA) cycle has emerged as a fundamental tool for continuous improvement. This iterative four-step management method, also known as the Deming Cycle or Shewhart Cycle, has its roots in the groundbreaking work of Dr. W. Edwards Deming, a pioneer in the field of quality control. PDCA provides a structured approach to problem-solving and process optimization, making it a vital component of modern quality management systems. In this comprehensive guide, we’ll delve into the intricacies of PDCA, its practical applications, and how it can be leveraged to achieve operational excellence.

The Genesis of PDCA

The PDCA cycle traces its origins back to the early 20th century when Walter A. Shewhart, a statistician at Bell Laboratories, introduced the concept of the “Plan-Do-See” cycle. However, Dr. W. Edwards Deming later refined and popularized the cycle, emphasizing the importance of continuous improvement in quality management. Deming’s principles of quality management, which include a focus on process improvement, data-driven decision-making, and employee empowerment, laid the foundation for the widespread adoption of PDCA.

Case Study Snippet: In the 1950s, Japanese manufacturers embraced Deming’s teachings, including the PDCA cycle, to rebuild their industry after World War II. The remarkable transformation result established Japan as a global leader in quality and efficiency.

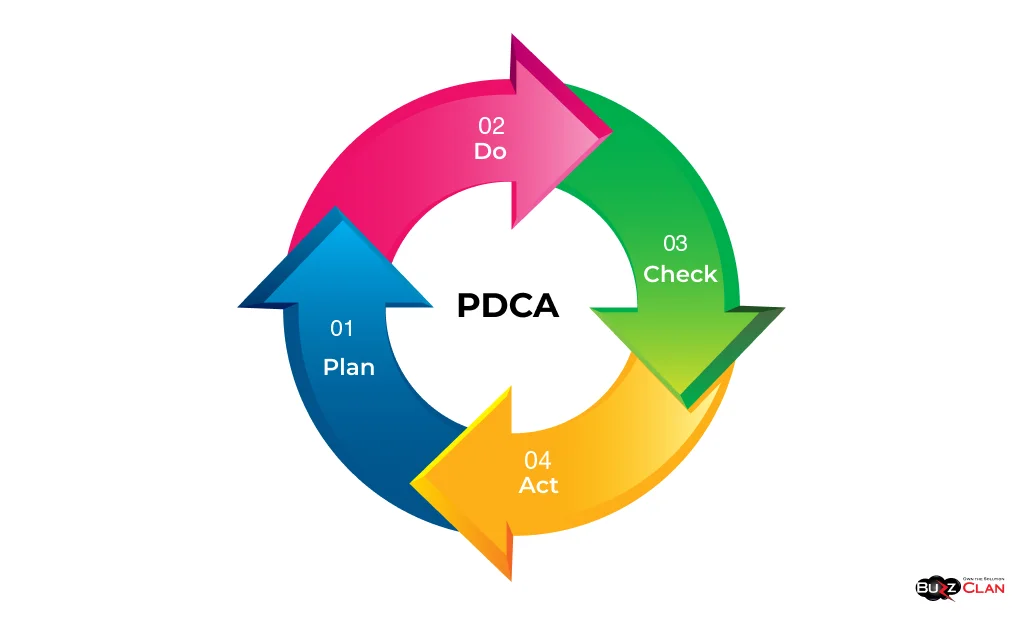

Understanding the PDCA Cycle

The PDCA cycle consists of four distinct stages

Plan: Identifying and Analyzing Opportunities

The planning phase involves setting objectives and processes necessary to deliver results based on the expected output. This stage includes:

- Defining the problem or opportunity

- Collecting and analyzing relevant data

- Setting goals and targets

- And developing an action plan

Tools for planning: SWOT analysis, brainstorming, and root cause analysis techniques like the Ishikawa (fishbone) diagram and 5 Whys can be used to identify improvement opportunities and develop effective plans.

Do: Implementation and Execution

The plan is executed in the “Do” phase, often on a small scale, to test its effectiveness. This stage involves:

- Implementing the action plan

- Documenting the progress

- And collecting data for analysis.

Cross-functional teams are crucial in this phase, bringing diverse perspectives and expertise to the implementation process.

Check: Evaluation and Analysis

The “Check” phase involves assessing the results of the implemented plan against the expected outcomes. This stage includes:

- Analyzing the collected data

- Comparing results with the goals and targets set in the planning phase

- Identifying any gaps or deviations

Key performance indicators (KPIs) and data collection methods should be established to facilitate effective evaluation and analysis.

Act: Continuous Improvement

The lessons learned from the “Check” phase are incorporated into the final phase, and successful processes are standardized. If the plan does not yield the desired results, the cycle begins again with a new plan. This stage involves:

- Taking corrective actions based on the analysis

- Standardizing successful processes

- Identifying areas for further improvement

Strategies for organizational learning, such as knowledge sharing and best practice documentation, are essential to ensure the benefits of PDCA are sustained and replicated.

PDCA in Action – Real-world Applications

The versatility of the PDCA cycle is evident in its wide-ranging applications across various industries and domains:

Lean Manufacturing

PDCA is a cornerstone of lean manufacturing, helping companies to continuously eliminate waste, improve efficiency, and enhance product quality. Toyota, a pioneer in lean manufacturing, has successfully employed PDCA in its Toyota Production System (TPS).

Healthcare: Improving Patient Care

Healthcare organizations use PDCA to improve patient care processes, reduce medical errors, and enhance patient satisfaction. For example, hospitals have applied PDCA to streamline medication administration processes, reducing errors and improving patient safety.

Software Development: Agile and DevOps

PDCA is inherent in Agile software development methodologies, such as Scrum and Kanban, emphasizing iterative development, continuous feedback, and process improvement. DevOps practices, like continuous integration and continuous delivery (CI/CD), also rely on PDCA principles to enable rapid, high-quality software delivery.

Environmental Management: ISO 14001

The ISO 14001 standard for environmental management systems incorporates the PDCA cycle to help organizations continuously improve their environmental performance. Companies can systematically identify, control, and reduce their environmental impact using PDCA.

At BuzzClan, we have extensive experience guiding organizations across industries in implementing PDCA to drive continuous improvement initiatives. Our team of quality management experts has helped clients optimize processes, reduce waste, and enhance customer satisfaction by leveraging the power of PDCA.

Integrating PDCA With Other Quality Systems

PDCA is not a standalone tool but rather a complementary approach that can be integrated with other quality management systems and methodologies:

ISO 9001 and PDCA

The ISO 9001 quality management standard is based on the Plan-Do-Check-Act (PDCA) cycle, a continuous improvement framework that organizations can use to achieve their quality objectives. The PDCA cycle is a four-step process that involves:

- Plan: In the planning phase, organizations identify their quality objectives, set goals, and develop plans to achieve them.

- Do: In the do phase, organizations implement their plans and take action to achieve their quality objectives.

- Check: In the check phase, organizations monitor and evaluate their progress toward quality objectives.

- Act: In the act phase, organizations take corrective action to address any nonconformities or areas for improvement identified in the check phase.

The ISO 9001 standard is structured around the four phases of the PDCA cycle, with each clause addressing a specific aspect of the process. For example, Clause 4 of ISO 9001 addresses the planning phase, Clause 5 addresses the do phase, Clause 6 addresses the check phase, and Clause 7 addresses the act phase.

Implementing ISO 9001 provides organizations with a framework for systematically applying the PDCA cycle across their processes. This can help organizations improve their quality management systems, achieve quality objectives, and meet customer needs.

Some of the benefits of implementing ISO 9001 include:

- Improved quality of products and services

- Reduced costs

- Increased customer satisfaction

- Improved employee morale

- Enhanced competitiveness

Organizations that are considering implementing ISO 9001 should be aware of the following challenges:

- The cost of implementation

- The time required to implement

- The need for employee buy-in

- The need for ongoing maintenance

Despite these challenges, implementing ISO 9001 can provide organizations several benefits that outweigh the costs and challenges.

Total Quality Management (TQM) and PDCA

Total Quality Management (TQM) is a comprehensive management philosophy that continually improves the quality of products, services, and processes. It is based on the belief that quality is not just a destination but a never-ending journey. TQM involves all employees in the organization, from top management to front-line workers, and it emphasizes the importance of customer satisfaction.

The Plan-Do-Check-Act (PDCA) cycle is a key component of TQM. It is a four-step iterative process that enables organizations to continuously identify improvement opportunities, implement changes, and monitor results. The PDCA cycle begins with the planning phase, where goals and objectives are established, and a plan is developed to achieve them. In the do phase, the plan is implemented, and process changes are made. In the check phase, the results of the changes are monitored and evaluated. In the act phase, adjustments are made to the plan based on the results of the check phase.

The PDCA cycle is a powerful tool for continuous improvement. It can improve any aspect of an organization, from product quality to customer service. By using the PDCA cycle, organizations can create a culture of continuous improvement that leads to better results.

Here are some specific examples of how the PDCA cycle can be used to improve organizational quality:

- Identify improvement opportunities: The PDCA cycle can identify improvement areas. Data on customer satisfaction, product quality, and other key metrics can be collected to do this.

- Implement changes: Once improvement opportunities have been identified, the PDCA cycle can be used to implement process changes. This may involve changing how work is done, introducing new technologies, or training employees.

- Monitor results: The PDCA cycle can be used to monitor the results of implemented changes. This is important to ensure that the changes have the desired effect.

- Make adjustments: The PDCA cycle can adjust the plan based on the check phase results. This ensures the plan is always up-to-date and aligned with the organization’s goals.

Six Sigma DMAIC vs. PDCA

Six Sigma is a comprehensive data-driven quality improvement methodology that aims to eliminate defects and reduce variation in business processes. It employs a structured approach known as DMAIC (Define, Measure, Analyze, Improve, Control). Each phase of DMAIC plays a crucial role in improving quality and achieving operational excellence.

| Phases of DMAIC | Description |

|---|---|

| Define | In the Define phase, the team clearly defines the problem they aim to address and sets measurable goals. This involves understanding the customer's requirements, identifying critical-to-quality (CTQ) characteristics, and establishing a project charter that outlines the scope, timeline, and resources required. |

| Measure | The Measure phase focuses on quantifying the current state of the process. The team collects and analyzes data to establish baselines, calculate process metrics such as defects per million (DPMO), and assess the stability and capability of the process. |

| Analyze | The Analyze phase involves identifying the root causes of defects and variations. The team uses statistical tools and techniques such as cause-and-effect diagrams (also known as Ishikawa diagrams), Pareto charts, and regression analysis to uncover the factors contributing to the problem. |

| Improve | The Improve phase is where the team develops and implements solutions to address the root causes identified in the Analyze phase. This may involve modifying work processes, implementing new technologies, or providing training to employees. The team uses statistical methods to validate the effectiveness of the implemented improvements. |

| Control | The Control phase ensures that the improvements implemented in the improvement phase are sustained over time. The team establishes control mechanisms such as standard operating procedures (SOPs), statistical process control (SPC), and regular audits to monitor the process and detect deviations from the desired performance levels. |

DMAIC shares similarities with the PDCA (Plan-Do-Check-Act) cycle, another iterative, problem-solving approach. Both methodologies emphasize the importance of data-driven decision-making and continuous improvement. However, DMAIC emphasizes reducing variation and defects, making it particularly suitable for manufacturing and other industries where quality is critical.

BuzzClan’s quality management consultants are well-versed in integrating PDCA with various quality systems and methodologies. We help organizations harmonize their quality initiatives, ensuring that PDCA complements and enhances their quality management efforts.

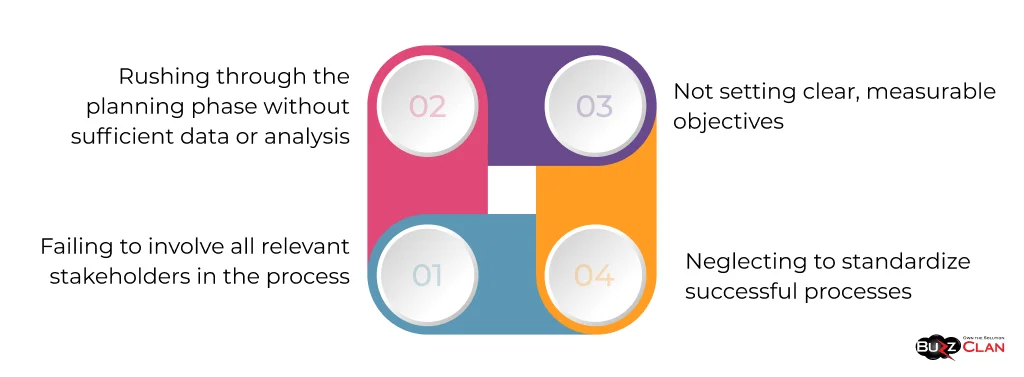

Challenges and Pitfalls

While PDCA is a powerful tool for continuous improvement, organizations may face challenges in its implementation.

Common mistakes in applying PDCA

- Rushing through the planning phase without sufficient data or analysis

- Failing to involve all relevant stakeholders in the process

- Not setting clear, measurable objectives

- Neglecting to standardize successful processes

Overcoming resistance to change

Implementing PDCA often requires a shift in organizational culture and mindset. Engaging employees, communicating the benefits of PDCA, and providing adequate training and support can help overcome resistance to change.

Ensuring meaningful data collection and analysis

The success of PDCA relies on accurate, relevant data. Organizations must establish robust data collection systems and analyze data effectively to drive informed decision-making.

PDCA’s Evolution – The Future of Continuous Improvement

As technology advances, the application of PDCA is evolving to leverage new tools and techniques.

Technological advancements and PDCA

The increasing availability of real-time data, advanced analytics, and machine learning transforms how organizations approach problem-solving and decision-making. These technologies can enhance the effectiveness of PDCA by enabling faster, more accurate identification of improvement opportunities and more precise monitoring of results.

PDCA in the digital age: Big data and AI

Big data and artificial intelligence (AI) can supercharge the PDCA cycle by processing vast amounts of data and identifying patterns and insights that may not be apparent to human analysts. For example, predictive analytics can help organizations anticipate quality issues before they occur, allowing for proactive planning and prevention.

Case study snippet: A leading technology company implemented an AI-powered PDCA system to optimize its software development process. The system identified improvement opportunities by analyzing data from multiple sources, including code repositories, issue trackers, and customer feedback. It recommended actionable insights, resulting in faster development cycles and higher-quality software.

BuzzClan stays at the forefront of these technological advancements, helping clients harness the power of big data, AI, and other emerging technologies to enhance their PDCA efforts. Our team can guide organizations in leveraging these tools to drive more effective, data-driven continuous improvement.

Implementing PDCA in Your Organization

Implementing PDCA in your organization involves a structured approach and adherence to best practices.

Step-by-step guide

- Secure leadership commitment and support

- Identify a pilot project or process for initial implementation

- Form a cross-functional team

- Provide training on PDCA principles and tools

- Follow the PDCA cycle: Plan, Do, Check, Act

- Document and share lessons learned

- Expand PDCA to other processes and areas of the organization

Best practices and tips for success

- Start small and scale up gradually

- Engage employees at all levels

- Set clear, measurable objectives

- Use data to drive decision-making

- Celebrate successes and learn from failures

- Continuously communicate progress and results

Tools and software that can help

- Project management tools (e.g., Trello, Asana)

- Data analytics and visualization tools (e.g., Tableau, Power BI)

- Statistical analysis software (e.g., Minitab, JMP)

- Collaborative platforms (e.g., Microsoft Teams, Slack)

BuzzClan’s quality management consultants can provide expert guidance and support throughout your PDCA implementation journey. From initial planning and training to ongoing monitoring and optimization, our team is dedicated to helping you achieve sustainable, long-term success with PDCA.

Conclusion

The PDCA cycle provides a proven, structured approach to driving ongoing enhancements in quality, efficiency, and customer satisfaction. By embracing PDCA as a core philosophy and integrating it into daily operations, organizations can foster a culture of excellence and resilience.

PDCA’s applications span diverse industries and domains, from manufacturing and healthcare to software development and environmental management. The cycle’s versatility and adaptability make it a valuable tool for any organization seeking to optimize processes, reduce waste, and enhance performance.

However, PDCA’s true power lies in its methodology and the mindset it cultivates. PDCA helps organizations develop the agility and resilience needed to thrive in an ever-changing landscape by encouraging a systematic, data-driven approach to problem-solving and emphasizing continuous learning and improvement.

At BuzzClan, we aim to empower organizations to unlock their full potential through continuous improvement. With our deep expertise in quality management and our commitment to staying at the forefront of industry best practices and technological advancements, we are well-equipped to guide you on your PDCA journey.

Whether you’re just starting to explore the benefits of PDCA or looking to enhance your existing continuous improvement efforts, BuzzClan is here to support you at every step.

FAQs

Get In Touch