Understanding Asset Monitoring: From Basics to Advanced Techniques

Priyanshu Raj

Jul 2, 2025

Imagine a world where your expensive machines decide to break down without a warning, IT infrastructure crashes become the new normal, and equipment chooses to play hide and seek with you. Well, if you are not keeping up with your asset monitoring efforts, this figment of imagination will turn into a reality. Luckily, businesses have been working proactively to eliminate such instances, and the asset tracking and monitoring market is set to hit a whopping USD 59.64 billion by 2032!

But what exactly is asset monitoring? Treat it like a health tracker for your physical and digital assets. The adage continues, “Prevention Is Better Than Cure.” Asset monitoring will help you track your assets’ health, performance, and location to reduce downtime, prevent losses, and maximize efficiency.

So, from manufacturing plants keeping a close eye on million-dollar CNC (Computer Numerical Control) machines to IT teams preventing their servers from catching a fever before a big event, asset monitoring has established its importance across industries. All that is fine, but what about the ROI?

With asset monitoring, you can reduce up to 20-30% of maintenance costs and eliminate close to 70% of breakdowns (Interesting insights Cost & ROI of Asset Monitoring await you on the journey). Sounds like music to your ears? Read on.

Key Components of Asset Monitoring

Unfortunately, attaching a sensor to a machine and waiting for a miracle will not help your digital asset management case. You will have to deal with several components. Let’s understand them closely.

- Sensors and IoT Devices: It is safe to call them tiny detectives, as they collect data on vibration, pressure, and temperature to ensure your assets stay in peak condition. If a temperature sensor were a detective, it would be responsible for keeping your ice cream ice-cold and preventing it from turning into a milkshake.

- Connectivity (Wired/Wireless Networks): Ever tried listening to your favorite song with broken headphones? The frustration is real, which will be similar to asset monitoring. You are set to invite trouble if you are not the best at Bluetooth, LPWAN (Low-Power Wide-Area Network), 5G, and Wi-FI. Jokes apart, each of these technologies will help you manage asset types and define the range of monitoring required.

- Data Processing & Analytics: Let’s say you are trying to get an investor for your manufacturing business, and your machine starts vibrating like a washing machine. In usual cases, it can become difficult to pinpoint the cause. However, with asset monitoring comes its best friend, data processing and analytics. They will not only log this machine failure but also analyze patterns and predict if your equipment can fail again, saving time and effort for your maintenance team. If we speak about numbers, you can cut unplanned downtime by up to 50%!!

- User Interface & Alerts: Tell us something: Do you like staring at endless raw data? Frankly speaking, no one likes it! For the same, asset monitoring tools help you with mobile notifications, dashboards, and automated reports. Look at it like this: If your machine’s motor has overheated, your asset monitoring software will tell your maintenance team, “Your motor has a high fever. Kindly fix it before it turns tantrumatic!”

- Integration with Other Systems: You must ensure that, be it ERP (Enterprise Resource Planning) software or CMMS (Computerized Maintenance Management Systems), they can establish a bond with your asset monitoring systems. And, why do we say that? It will eliminate room for surprises, let the data flow smoother than butter, and allow for improved decision-making.

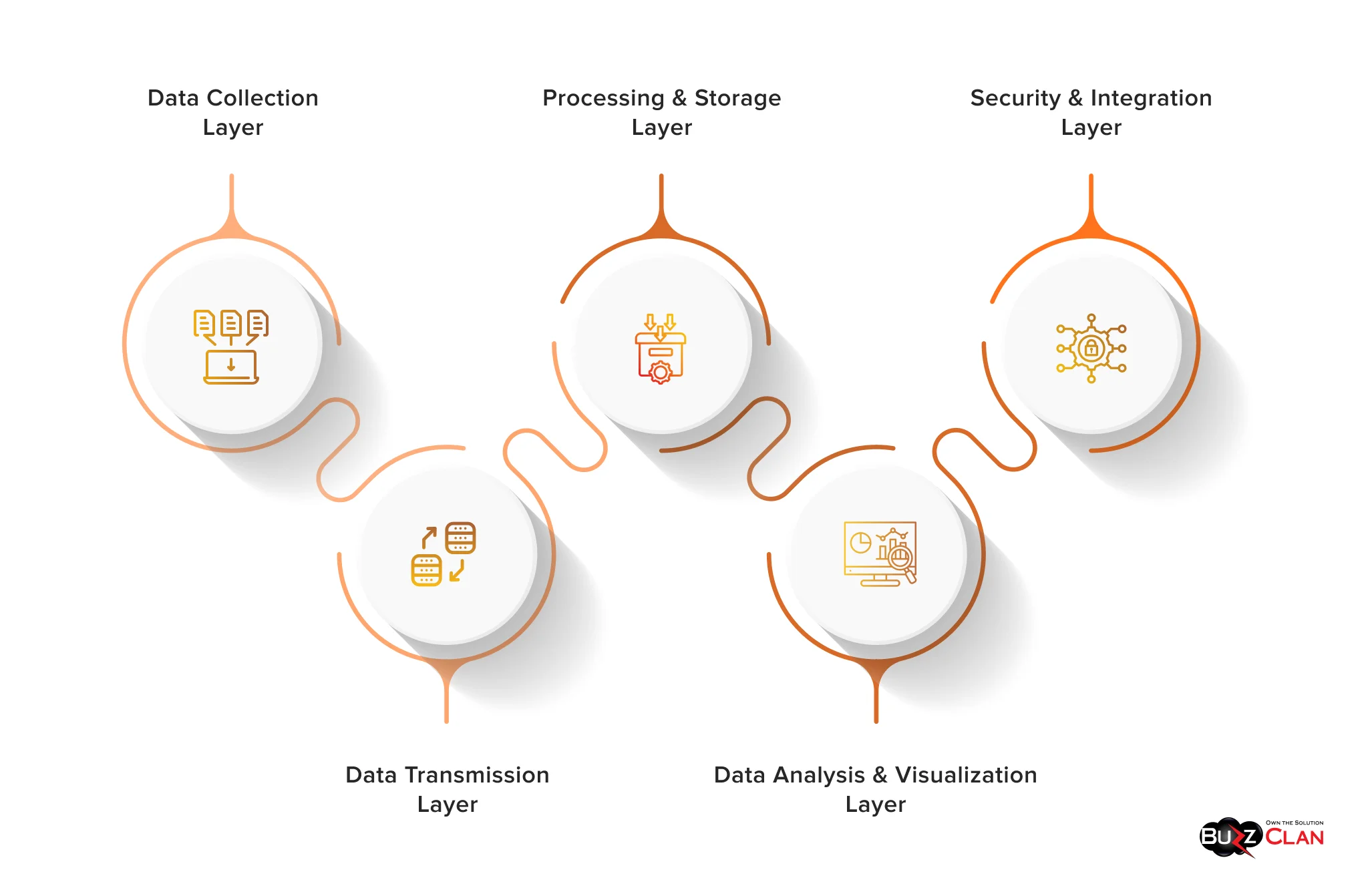

Asset Monitoring Architecture

It is time to examine the blueprint for asset monitoring solutions. Once you reach the end, you will find something more precious than gold, spelled D_A_T_A. The system is full of layers, and each plays a role in ensuring your assets don’t mysteriously disappear. Let’s have a look.

Data Collection Layer

Think of this layer as overprotective parents. Multiple sensors and IoT devices cling to your assets in this layer and constantly check temperature, location, usage, patterns, and humidity. And what are these protective parents’ favorite weapons? They rely on RFID, GPS, and Bluetooth to check assets in real time and ensure nothing slips through the cracks. Once satisfied with their checks, they hand over the assets to a gateway device. The latter makes the data worthy by aggregating and preprocessing it.

Data Transmission Layer

Eventually, the gateway must send the sensor data to the central server or cloud platform. However, the gateway cannot be treated as a one-man army. You must decide whether it must be sent through wireless networks or LPWAN. To ensure the data is not lost in the jungle, you need to buckle them with GPS and seatbelts for data transmission.

Processing and Storage Layer

It is time for cloud servers, data centers, and edge computing nodes to play a role in the upkeep of assets. They process, refine, and filter the data like a librarian manages a massive book collection. While edge computing will help you find books kept nearby faster, cloud servers will help you maintain heavy storage of books and track where they are. At the same time, Databases are your saviors, aka memory banks. With them by your side, you will never lose keys and ensure the safekeeping of your data.

Data Analysis and Visualization Layer

Now that the data is stored, you can sigh relief. But, what is the next step? Well, AI, machine learning, and analytics engines are the detectives that will help you extract meaningful insights from the data. Much like a fortune teller, but with data-backed insights and not merely intuition! With them, you can optimize asset use and improve maintenance strategies while enjoying the perks of organized data with dashboards, reports, and real-time visualizations through web applications.

Security and Integration Layer

It is time to introduce the system’s bodyguard—the security and integration layer. These layers protect your assets from data theft, breaches, and insider threats. They are named access control, regular audits, and encryption. At the same time, when you integrate ERP, CRMs, and CMMS with your assets, you will leave no room for tantrums. Ultimately, an asset monitoring system ensures you can sit back, relax, and let technology do the detective work instead of sending out a search party for misplaced equipment.

Types of Assets That Need Monitoring

Let’s be honest: not all are created equal. Some will work well with regular check-ins, while others need dedicated babysitting.

Fixed Assets (Machinery, Equipment, Infrastructure)

They are heavy-duty assets that are strong, reliable, and built to last longer. However, they are gym freaks and require their maintenance workouts. If you are not monitoring them, they are equivalent to your friend who was deadlifting 300 lbs but now complains of back pain. Close to 82% of companies have experienced unplanned downtime in the last three years, costing them up to $260,000 per hour!

IT Assets (Servers, Data Centers, Network Devices)

We all have that one friend who panics when their battery hits 10%. They are always on the edge and need attention. Yes, drama queens/kings are your IT assets! If they don’t receive the much-needed attention, they can demand it by crashing at the worst possible time. Moreover, the average cost of IT downtime is $12,9 per minute. So, get the cue and get going!

Fleet & Transportation (Vehicles, Ships, Drones)

What if you had the chance to go on a road trip that never ended? But, where on earth do we find such excellent vehicles and equipment? Jokes apart, fleet assets like ships, drones, and cars can break down when needed. So, to save yourself the dilemma, cut fleet repair costs and extend their lifespans by 20-30%. It is time to up your asset monitoring game.

Inventory & Supply Chain Assets

Can you play a game of Legos without the building blocks? Sounds absurd. This is where the role of managing inventory with monitoring comes in. Yes, just like toys, your products get lost, shipments get delayed, and your customers get angry. Inefficient, poor inventory management leads to losses worth $1.1 trillion globally annually. Spare yourself the trouble and integrate asset monitoring at the crack of dawn!

Energy & Utility Assets

Turbines, substations, and power grids have to be monitored closely. You may never know, but they have a mood swing, and half the city darkens. Yes, soak that in! How about charging your phone at a cafe and searching for candles like the 1700s? Still not convinced? Well, power outages cost the U.S. economy close to $150 billion per year. Now, you know precisely why you should monitor energy and utility assets.

Healthcare Equipment

It is time to stop taking machines for granted, especially in healthcare. MRI machines, infusion pumps, and ventilators are designed to save lives. But who will protect them? According to the WHO, in the U.S., 30% of medical equipment failures result from poor maintenance. Luckily, AI-powered monitoring can breathe life into your machines by reducing downtime. So, if your hospital is missing any devices, it is time to get them married to IoT trackers.

Human Resources

An office is filled with workaholics, master procrastinators, and low-key employees. Often, monitoring tools are used to track attendance and productivity, and check if employees are giving their best. While some companies experienced a boost in productivity, employees felt it was killing their morale (more than their micromanaging bosses!). An example is that of a Canadian accountant who was ordered to repay $2000 for time theft. While she was paid for 50+ hours, she only worked for 30! Yes, alt-tabbing between Excel and entertainment platforms didn’t help her case.

Digital & Intellectual Property

Imagine the frustration when you spend years designing a perfect logo, software, or song, and some random business adds it to a t-shirt. Digital asset monitoring will help you protect your patents, trademarks, and copyrights from digital pirates. Due to pirated movies and shows, Disney lost billions in revenue. They then shifted to AI-driven monitoring that helped them catch the culprits faster than Marvel releases!

Now that you know the assets you must monitor, here are the estimated costs.

| Asset Type | Estimated Cost |

|---|---|

| IT Assets | $500 - $50,000+ |

| Financial Assets | $100 - Millions |

| Manufacturing Equipment | $5,000 - $500,000+ |

| Energy Assets | $2,000 - $ 1 M+ |

| Healthcare Equipment | $500 - $ 3 M+ |

| Inventory & Stock | $100 - $Millions |

| Security Systems | $500 - $100,000+ |

| Employee Monitoring | Varies ($10 - $500 per employee per month) |

| Digital & Intellectual Property | Varies (Few $100s to Millions) |

Basic Techniques of Asset Monitoring

Now, let’s talk about the techniques to monitor assets, as only sensors don’t suffice!

Condition Monitoring

More like a regular health check-up for your assets. Sensors help you check vibration, temperature, and pressure to detect anomalies. You can prevent a significant failure for your wind turbine as sensors can spot early signs of imbalance.

Real-time Tracking & GPS Monitoring

Real-time tracking lets you heave a sigh of relief by doing the detective work and ensuring your logistics are in line and no one steals them. This is why Amazon uses GPS and RFID to track millions of packages daily.

Remote Asset Monitoring

Imagine keeping an eye on your wind turbines from your cozy office, your IT admin ensuring your servers are not overheating while sipping boiling coffee. Well, cloud-based solutions let you do that while saving time and resources. A win-win!

Automated Alerts & AI-driven Insights

Let’s be honest. Would you like to leave your sleep to fix a system failure at 4 AM? Fret not, automated alerts will notify your managers when something goes wrong. AI goes a step ahead by detecting trends and suggesting optimizations.

Common Challenges in Asset Monitoring

While asset monitoring seems easy, it is like trying to pacify a group of hyperactive toddlers (each with a specific demand). You will encounter some common challenges, from tracking errors to cyber threats. Outsmart them before your assets decide to go into oblivion!

Data Overload

It has been said time and again. Too much of anything is bad. It holds for GPS tracking, AI analytics, and IoT sensors. They generate much data that humans or computers cannot process efficiently. Delta Air Lines was at the receiving end of it in 2017, when it suffered a significant IT failure due to their outdated infrastructure. The result was that thousands of flights were cancelled. If you wish to save your business from such disasters, you must befriend smart data filtering, AI-driven insights, and cloud-based storage, as they will help you separate critical updates from the unimportant ones. This means keeping the operational joy and saying goodbye to the clutter.

Integration Nightmares

Businesses often choose to use a mix of legacy systems and modern technology, and it turns into a disastrous recipe, much like a parent/grandparent who refuses to upgrade their flip phone. In 2018, Maersk, a global shipping giant, faced massive disruptions and losses worth $300 million when a cyberattack decided to play with its outdated infrastructure. Post that, they invested in scalable platforms, API-based integration, and middleware solutions to ensure all their systems are on the same page, and don’t get passive-aggressive now and then.

Security Breaches

Did you know that hackers love asset monitoring systems as they hold the treasure (valuable data and control critical operations)? In 2021, a water treatment plant in Florida was hacked. Attackers tried to poison the water supply by adjusting levels of sodium hydroxide to 11,100 parts per million from the original 100 parts per million. We need not say how dire the consequences could have been if a vigilant employee hadn’t foiled the intrusion attempt. The cure for this menace now and in the future is leveraging AI-powered anomaly detection, multi-factor authentication, and top-notch encryption to spot threats before they become a flourishing disaster.

Asset Loss & Misplacement

Fact check: Assets can go missing even with tracking technology at your disposal. Don’t believe us? Well, a Malaysian Airlines Flight MH370 vanished, proving that even multi-million-dollar assets can be lost in the absence of proper tracking. The only solution is to adopt real-time monitoring, using GPS tracking, geofencing alerts, and RFID tags. Let’s be honest, they are assets and must always be protected.

Human Error

Do you also think the “My Bad” factor refuses to get off your back? Despite technological advances, humans remain the weakest link (No prizes for this consistency, though!). In 2017, an Amazon employee wrote the wrong command that took down significant services like Slack, Netflix, and Airbnb. The lesson is to implement strict access controls, automate critical processes, and provide adequate employee training, as there is no room for last-minute disasters.

While challenges are inevitable, the right mix of security, automation, and proactive planning will make things smoother than ice. And if you fail, just remember that even enterprises mess up. The key is learning, adapting, and guarding your assets like your life.

Advanced Asset Monitoring Techniques

As industries evolve, so will asset monitoring techniques. If you still rely on traditional methods, be prepared to lose millions. Otherwise, the best way is to use these cutting-edge technologies.

Predictive Maintenance (PdM) with AI & Machine Learning

We all have that friend who can sense drama beforehand. Consider predictive maintenance the same for your assets. While your friend relies on intuition and experience, predictive maintenance relies on AI and ML to predict circumstances when an asset can fail. Not only can you be proactive on fixed schedules, but you can also ensure cost savings as maintenance takes place only when needed.

So, what process runs inside the predictive maintenance engine? The historical sensor data is first analyzed like a detective to find failure patterns. Machine learning models segregate valid data and post that alerts are triggered when anomalies are found. PdM will schedule repairs based on real-time data and give you ample time. Make the best use of that, as you don’t need to deal with unexpected breakdowns, and the asset lifespan improves without manual intervention.

Digital Twin Technology

One asset is never enough! A digital twin is a virtual replica of a physical object. The best part is that it is continuously updated with real-time data. It is much like a clone of your machine, which doesn’t face an actual breakdown! It just does the simulation part and tells you when and why. And, how does this happen? Well, a 3D model of the asset is created, and IoT sensors then feed real-time data into the twin. Post that AI models take over and make predictions, how assets will perform under diverse conditions. Siemens leverages the power of digital twins and has thus reduced design errors by 50%.

Self-Healing Assets with AI & Nanotechnology

Close your eyes and imagine what would happen if your phone’s repaired, cracked screens, and coffee machine fixed themselves before a Monday morning breakdown. Don’t let that imagination lie a slow death! Yes, soak that in, as that is the future you are heading towards. Cutting-edge asset monitoring systems now include AI-powered automated repairs and self-healing materials. And, what happens inside these machines?

Well, machines first identify their weaknesses and realize they should take better care of themselves. Then, self-repairing particles fill in gaps before they turn into a menace. This is similar to having microscopic construction workers with no complaints and demands! With self-healing assets, we are just a few years away from receiving passive-aggressive messages from assets you have ignored.

This is why NASA is working earnestly to develop self-healing polymer materials for its spacecraft. These materials will reduce maintenance needs and ensure more extended mission durability.

AI-Driven Computer Vision for Asset Inspection

Imagine an AI inspector scanning your closet and saying, “ That pair of trousers is from 2010. Please discard it immediately!” Computer vision systems depend on AI to detect wear, defects, and corrosion. Gone are the days when clipboards and magnifying glasses inspect every inch of oil rigs. Luckily, cameras capture images of assets in real-time, and AI models perform the analysis work and trigger alerts for human review or automated repairs. BP (British Petroleum) has reduced manual inspection times by 80% with AI-driven drones to inspect offshore oil rigs.

Blockchain for Asset Tracking and Security

Treat blockchain like that one friend who remembers every embarrassing thing you do. Luckily, asset tracking takes care of your actual assets, not your Karaoke fails. “Oops, I lost it” becomes a thing of the past with blockchain, as asset transactions and movements are recorded in a tamper-proof ledger. And, how does all this take place? Well, assets are first assigned unique blockchain-based IDs.

All maintenance events, movements, and ownership transfers are recorded as transactions. Lastly, smart contracts help you automate processes and give a sigh of relief! This is why Walmart has been using blockchain to track food supply chains. They have reduced the time needed to trace contaminated products from 7 days to 2.2 seconds.

Edge Computing for Real-Time Asset Monitoring

Nobody likes delays, and that is precisely why edge computing exists! Instead of sending all the asset data to the cloud and waiting for a million years, edge computing processes information locally. This leads to fewer delays, faster response times, and real-time decision-making. And, how is that made possible? Well, edge devices and AI-based anomaly detection systems help you spot problems before they become disasters. At the same time, 5G & LPWAN Networks ensure the information flows smoothly with zero obstacles. This is why Tesla cars use onboard edge AI to process real-time sensor data rather than calling Elon Musk for advice now and then!

Remote Monitoring with Augmented Reality (AR) & Wearable Tech

Do you know the best thing about AR and wearable technology? They turn technicians into high-tech superheroes. We know that flipping through a 500-page manual is boring, but how about AR apps taking over with smart glasses that overlay real-time machine data, maintenance instructions, and alerts directly onto your physical assets? All this becomes possible with X-ray vision-like machines, IoT-connected gloves, and the old cloud and 5 G. They help you quickly diagnose problems and fix assets on your office’s comfortable bean bag. This is why Boeing depends on Microsoft HoloLens to reduce inspection errors and improve repair efficiency massively.

Role of IoT in Asset Monitoring

IoT seldom receives the praise it deserves for its contribution to asset monitoring. And why do we say that? It has been a trailblazer in turning a manual headache into a futuristic marvel—more like giving your machines a sixth sense! This means you can look forward to optimized performance minus the breakdowns.

Manufacturing companies, retailers, and logistics giants are all leveraging the benefits of IoT. Shall we spill a secret? Even cows decided to pledge their support to IoT. And how was that possible? Farmers started using smart collars to track their health and boost dairy production by incredible margins. IoT leaves no room for slacking—even for the laziest players- machines.

Real-Time Data Analytics in Asset Monitoring

Real-time data analytics are your best allies as they let you know what is happening with your assets before they start making noise! With consistent data collection and analysis, you can detect early warning signals, optimize performance, and avoid unexpected downtime—more like asset monitoring with superpowers instead of waiting for machines to scream for help.

Key Technologies Used

- Industrial IoT Sensors: Machines can’t talk, so sensors detect their pains and conditions, such as pressure, vibration, and temperature.

- Edge Computing: Data is processed locally instead of waiting for the cloud to respond.

- AI & Machine Learning: Using past failures to save future disasters and dramatic shutdowns.

- Digital Twins: Virtual cloning as a real-world trial is pretty expensive.

- 5G & Cloud Connectivity: This ensures data moves faster than your IT team trying to fix an outage before the boss notices. Use it to fix outages before anyone, or worse, your customers see it!

Shell’s Oil Rig Monitoring cut down its unplanned shutdowns by 15%, saving $100 M annually with AI-powered real-time monitoring. The question is, when are you getting such phenomenal results?

Cost Breakdown of Implementing Real-Time Data Analytics

Here is a detailed breakdown of your costs while implementing real-time data analytics for your assets.

| Component | Estimate |

|---|---|

| IoT Sensors | $10 - $500 per unit |

| Edge Devices | $500 - $5,000 per device |

| Cloud Storage & Processing | $0.02 - $0.10 per GB |

| AI & Machine Learning Software | $5,000 - $50,000 annually |

| Dashboard & Reporting Tools | $2,000 - $20,000 annually |

| Cybersecurity Measures | $5,000 - $50,000 annually |

| Implementation & Training | $10,000 - $100,000 |

On-Premise vs. Cloud-Based Asset Monitoring Solutions

Choosing between on-premise and cloud-based asset monitoring solutions is like owning a robotic watchdog or a pet tiger. While on-premise solutions will give you complete control and security, they will cost 3 to 5 times more. At the same time, cloud-based solutions are low maintenance and accessible anytime, anywhere. Let us help you make a choice.

| Feature | On-Premise Asset Monitoring | Cloud-Based Asset Monitoring |

|---|---|---|

| Deployment | It is installed on local servers, and maintenance is handled in-house. | These asset monitoring systems are hosted on remote cloud infrastructure and handled by third-party providers. |

| Initial Cost | The initial costs are higher, and you must establish a dedicated budget. | Luckily, you can take advantage of subscription-based models and lower upfront costs. |

| Operational Cost | Energy costs, salaries for IT staff, and maintenance make for operational costs. | IT costs are recurring and minimal. |

| Data Security | There is full control over compliance and security. | You may face compliance concerns as cloud providers manage the security. |

| Accessibility | The accessibility is limited to a local network or VPN. | You can access it anytime and anywhere with the internet. |

| Scalability | Requires additional hardware and setup for scaling | Easily scalable with cloud resources |

| Maintenance & Updates | Managed in-house, requires an IT team for upgrades | Handled by a provider with automatic updates |

| Reliability & Uptime | Depends on the in-house infrastructure & backups | Typically offers high uptime with redundancy |

| Customization | Highly customizable | Limited customization |

| Integration | Requires manual integration with other systems | Easier integration with cloud-based APIs |

| Backup & Disaster Recovery | Requires in-house backup strategies | Built-in cloud backups and disaster recovery options |

Security Considerations in Asset Monitoring

By now, you know that asset monitoring is not just about fancy technology but vigilance, learning from past mistakes, and common sense. If you are protecting a warehouse or a data center, the key is to think like a hacker and think about what could go wrong. Because when it comes to security, there is no better survival strategy than “Better Safe Than Sorry.”

Unauthorized Access

Unauthorized access from a cybercriminal or a vengeful employee is not a welcome move. You have to do all that it takes to abort the mission. The colonial pipeline attack in 2021 led to significant fuel shortages in the U.S. While you may not be dealing with fuel shortages, you must protect your “fuel” with utmost precision. Thus, strict access controls and multi-factor authentication should be placed on a high pedestal. Let’s be frank: why are you leaving assets in the lurch if you are not lending to strangers or borrowing your debit card?

Data Breaches

Ask the aftermath of data breaches to those 147 million people whose personal information was exposed in the Equifax 2017 breach. Don’t let that happen to your business. First, use regular security patches, treat encryption like a diktat, and make intrusion detection systems your best friend. You don’t open your front door because someone doesn’t break in. Get the cue and take the right action!

Physical Theft

Let’s understand that even the best of digital security techniques cannot save you if someone decides to walk away with your assets. So, it is time to put a bell on your cat, tie your assets with RFID tags, and enable GPS tracking.

System Downtime

Chaos ensues when asset monitoring systems go down! In 2021, Facebook went offline globally due to a faulty server configuration, leading to a loss of $160 million. The fix lies in simple solutions, regular disaster recovery drills, redundant backups, and failover systems. Nothing can ruin your day more than realizing your critical data is stuck.

AI Threats to Asset Monitoring

AI is a double-edged sword. On one hand, it is revolutionizing asset monitoring, on the other hand, hackers are manipulating AI models and launching automated cyber attacks faster than you say “Cheese”. In 2023, researchers tricked Tesla’s AI into running a stop sign by placing a tiny sticker, proving that even intelligent systems can be dumb. And, how did they solve this? Well, if you can’t beat them, join them! Make AI fight with AI and regularly audit models while maintaining human oversight. Ignore it if you want AI to lock you out of your system!

Compliance Challenges

Ensuring compliance in asset monitoring can feel like herding cats, with regulators keeping a close check. Many companies struggle with asset tracking compliance due to human errors or outdated systems. Manufacturers have been casually slapped with a $10 million penalty for not maintaining proper records. Luckily, saving your business from such mishaps is easy! Use advanced IoT solutions and AI-driven monitoring to keep a tab on assets and avoid regulatory nightmares.

If fulfilling security needs is costly, try managing your business budgets after a breach. The choice is yours! Let’s look at the estimated costs.

| Security Consideration | Estimated Implementation Cost | Impact on ROI | Breach Cost Losses |

|---|---|---|---|

| Access Control & Authentication | $10,000 | You can say goodbye to unauthorized access and reduce the risk of theft and fraud. | $500,000 |

| Network Security | $5,000 - $20,000 | Guaranteed asset data integrity and prevention of cyber intrusions. | $1M+ |

| Surveillance & Physical Security | $15,000 | Eliminate instances of theft and unauthorized asset handling. | $200,000 + |

| IoT & Real-time Monitoring | $30,000 | Enhanced efficiency, reduced downtime, and improved asset utilization await you! | $750,000 + |

| Incident Response & Backup Systems | $10,000 - $50,000 | Reduces downtime in case of a cyberattack or failure | $500,000+ |

| Compliance & Security Audits | $5,000 - $25,000 per year | Ensures regulatory compliance, avoiding fines | $1.5M + |

| AI-driven Threat Detection | $50,000+ | Early detection minimizes risk exposure | $2M+ |

Further Reading

Best Practices for Asset Monitoring

Like we said before, there is not much difference between asset monitoring and babysitting. The only difference is that you are dealing with expensive equipment, inventory, or vehicles. But the good news is that you don’t need to hover around them. All you need to do is install cameras with robotic hands (read that following best practices), and you can be stress-free (for real).

Use Real-Time Tracking

Yes, guesswork is last century, and you cannot expect it to protect your assets. Whether FedEx or any e-commerce store, they do real-time tracking with GPS devices, RFID tags, and IoT sensors, and know precisely how assets perform. So, spare yourselves the horror stories and remember the numbers we mentioned earlier ( Asset tracking market to hit $34.8 billion by 2028) to keep your stuff in check and prevent reputational damage for your business.

Automate Maintenance

If you wish to deal with expensive breakdown drama, it is better to skip this paragraph! Yes, imagine WiFI going haywire before a vital client call or report submission. Luckily, with predictive maintenance, you can prevent such disasters. Just like General Electric, it uses digital twins to predict failures. Not only is downtime reduced, you will also witness a steep drop in maintenance costs. If you still rely on “Wait till it breaks”, it is better to donate that money to charity!

Keep Your Data Organized

It is time you realize that spreadsheets are not magicians. We are sorry to say this, scattering your asset data across multiple Excel files, sticky notes, and a whiteboard is a recipe for disaster. Walmart swears by RFID technology to keep a strict check on its inventory and keep customers happy. If you are still manually entering data, make room for huge errors. And, if this is something that doesn’t sit well with you, it is time to use a centralized asset management system that keeps maintenance schedules, usage history, and everything else on track.

Set Up Alerts

Surprises are highly overrated when it comes to machines. Would you like to get stranded on a highway? We can hear a clear no! So, it is time to adopt innovative monitoring systems that send real-time alerts when something can go wrong. The oil and gas industry uses these to detect early leaks, prevent environmental damage, and save millions in damages. The lesson? Don’t ignore the warning signs unless you wish to end up in the news (not in a good way).

Optimize Asset Utilization

Idle assets cost you money. Let asset utilization reports reduce your financial burdens and give insights on what’s collecting dust and what needs reallocation. And, we don’t say it just like that. Even Uber abides by our statement. This is why they optimize their fleets with real-time data and balance their supply and demand like a child’s play. So, it is time to think 100 times before adding expensive equipment and say yes to asset optimization. Why, if you may ask? Well, increased efficiency never hurt any business!

Prioritize Security

Yes, because thieves have an affinity for expensive toys. Similarly, assets are subject to wear and tear and are primary targets for theft. Construction companies lose $1 billion annually due to stolen equipment. You can save your business from these troubles with geofencing technology. Your systems will trigger an alert if your assets move outside a designated area. Companies like Caterpillar depend on geofencing to protect their heavy machinery and ensure a sound sleep as their expensive bulldozers stay within their limits!

Regularly Review and Improve Your System

Tech keeps evolving, and so should your asset monitoring solution. There was a time when BlackBerrys ruled the roost regarding mobile technology. Thus, it helps to review and upgrade your system to ensure peak efficiency regularly. You may reduce operational costs by significant numbers! Therefore, don’t treat your system like that old gym membership; use it to improve your asset health over time.

Industry Specific Asset Monitoring

Asset monitoring is no different than being a nosy neighbor who keeps an eye on you. However, it also helps you prevent health and performance issues. While asset monitoring in manufacturing is all about giving each machine a smartwatch, in IT, it is babysitting servers to ensure they don’t overheat. So, asset monitoring is the unsung hero, preventing oil rigs from leaking or ensuring hospital equipment doesn’t fail during a high-end surgery. Let’s have a look at how different industries protect their assets.

| Industry | Asset Monitoring Focus |

|---|---|

| Manufacturing | The focus is on predictive maintenance, maintaining sound equipment health, and lowering downtime. |

| Healthcare | The objective is to ensure asset utilization, track medical devices, and ensure regulatory compliance. |

| Logistics & Supply Chain | Fleet tracking, condition monitoring, and inventory management are the primary focus. |

| Retail | Retailers prevent thefts, manage inventories, and optimize supply chains with asset monitoring. |

| Energy & Utilities | Remote monitoring of pipelines, power grids, and predictive maintenance is possible with robust asset monitoring solutions. |

| Aerospace & Aviation | Aircraft maintenance tracking, fuel efficiency monitoring, and safety compliance are all handled with asset tracking. |

| Smart Cities | Traffic and waste management & public transport tracking make a breeze with asset monitoring. |

Cost & ROI of Asset Monitoring

Investing in asset monitoring is like hiring a personal detective for your equipment, minus the drama. While there are upfront costs for sensors, software, and integration, the ROI makes it worth it. Instead of playing hide-and-seek now and then, how about getting clear insights in real time and reducing the surprise elements? In short, asset monitoring pays for itself—unlike gym membership, which is long lost in oblivion.

| Factor | Estimated Cost (USD/Year) | Estimated Savings/ROI (USD/Year) |

|---|---|---|

| Hardware (Sensors, IoT Devices) | $20,000 | - |

| Software & Analytics Platform | $10,000 | - |

| Installation & Setup | $5,000 | - |

| Maintenance & Support | $7,000 | - |

| Training & Workforce Adaptation | $3,000 | - |

| Total Cost | $45,000 | - |

| Reduction in Unplanned Downtime | - | $60,000 |

| Extended Asset Lifespan | - | $20,000 |

| Optimized Maintenance Costs | - | $15,000 |

| Improved Operational Efficiency | - | $10,000 |

| Total Savings | $105,000 | |

| Net Profit (Savings - Cost) | - | $60,000 |

| Net ROI | Net ROI- | $60,000 (133%) |

Tools For Asset Monitoring

Let’s look at the top weapons, aka tools, for asset monitoring to smooth the sail.

| Tool | Key Features | Pricing | Free Trial |

|---|---|---|---|

| IBM Maximo | Integrates seamlessly with IoT sensors and gives a comprehensive asset health score. |

|

No |

| SAP EAM (Enterprise Asset Management) | Best for comprehensive lifecycle management and integrating with third-party applications. Businesses worldwide use the tool for its predictive maintenance capabilities. | Custom pricing | No |

| GE Predix APM | The tools, asset performance management, and predictive analytics make it necessary for businesses. | Custom pricing | No |

| Siemens MindSphere | Best for IoT-as-a-service, real-time analytics, and industries with high scaling needs. | Custom pricing | No |

| UpKeep | The tool will help smooth work order management and get your maintenance schedules on track. |

|

Yes |

| Fiix by Rockwell Automation | Best for asset management and provides seamless integration with IoT sensors. AI-predictive maintenance is a bonus. |

|

Yes |

| Asset Panda | The tool is known for its robust reporting capabilities and customizable asset tracking. | Custom pricing | Yes |

| AWS IoT SiteWise | The tool is best used for organizing industrial data and collecting real-time metrics and analytics. | Pay-as-you-go pricing | Yes |

| Senseye PdM (Predictive Maintenance) | Best used for real-time condition monitoring and predictive maintenance analytics. | Custom pricing | No |

Advanced Topics in Asset Monitoring

It is time to go beyond nuances and dive into the world of asset monitoring.

Role of DevOps in Asset Monitoring

Don’t we all have a super organized colleague or leader who knows exactly where their phone, keys, and wallet are? The secret is that they have a system for everything. DevOps’s role is the same regarding proactive alerting, CI/CD pipelines, and automation. They ensure that your systems don’t misbehave at the last moment. DevOps is a favorite of IT teams as they can depend on monitoring tools to detect issues and trigger self-healing scripts rather than racking their brains to discover why a machine went down. More like a butler who has your coffee machine fixed before you realize it went awry in the first place.

Containerized Environments in Asset Monitoring

Imagine packing for a trip where you can pack every item into tiny, unbreakable boxes. This is what containerized environments do for asset monitoring. As all your assets, including datasets, microservices, and applications, are packaged into containers, monitoring, scaling, and predicting their behavior becomes easy. But what if containers decide to turn into a diva? Monitoring tools will help isolate the troublemaker and save your system from the dilemma!

Cloud-Native Applications in Asset Monitoring

Don’t we all love food delivery apps? They are available anytime, anywhere, scalable, and super efficient. Regarding asset monitoring, cloud-native applications do the work of food delivery; wherever your assets are, they work seamlessly! But, what makes them different than traditional monitoring systems? They help you with real-time insights, anomaly detection, and predictive analytics, more like a virtual assistant who reminds you of breakdowns before they happen.

Role of DevSecOps in Asset Monitoring

DevSecOps is an overprotective parent who monitors their kid’s location and installs cameras in the fridge (to prevent overeating snacks at midnight). Well, DevSecOps does the same but for IT infrastructure. It ensures that security is baked into every development, deployment, and operation step, so nothing slips through the cracks. If a developer pushes a new update, DevSecOps will not say “Good Job!”. Instead, it will check for compliance, interrogate your code, and scan for vulnerabilities. This means whenever a cybercriminal tries to meddle with your system, DevSecOps is 10 steps ahead, laughing at the foiled attempt!

Observability in Asset Monitoring

Treat this like a security guard at a high-tech museum who knows what is happening in and out like the back of their hand. This is what observability in asset monitoring does. It doesn’t wait for disasters to occur! Instead, it gives you metrics, logs, and real-time insights to predict problems before they happen. If there is a manufacturing plant, IoT sensors warn before the maintenance person gets reprimanded for turning the whole factory into a lava pit.

Zero Trust Architecture

Let’s welcome the paranoid bouncer of cybersecurity. Any guesses? If you guessed Zero Trust Architecture, we salute your tech acumen. ZTA will not let you go to the nightclub before you submit your ID and verify your details. It refuses to trust you. Similar is the case with cybersecurity. Even if your employees log in from their office systems, ZTA will verify their credentials. It would not be wrong to say that this bouncer spares no one and has eyes that are better than all spies combined.

Further Reading

How to Choose the Right Asset Monitoring Solution for Your Business?

Imagine running a business with all kinds of expensive machinery, vehicles, and inventory, and you have no idea where or how they are performing. It is like trying to hit the bull’s eye with a blindfold! Luckily, this is where asset monitoring solutions step in. However, with a sea of options, how do you select the right one? Let us tell you how.

Identify What You Need to Monitor

The first thing is to develop clarity on the assets you own, as different industries have different needs. For logistics, you need GPS tracking to monitor your fleet. In manufacturing, equipment should be up and running to prevent unexpected downtime. Per Deloitte, predictive maintenance can reduce maintenance costs by 25% and unplanned outages by 50%. So, be very careful and precise about your needs.

Consider Real-Time Tracking Capabilities

What if airlines didn’t track planes? You would end up waiting at the gates, pilots playing hide-and-seek, and chaos would earn a crown. The same is the case with your business. Whether GPS trackers, IoT sensors, or RFID tags, real-time tracking helps ensure smooth operations and best-performing assets. Amazon uses asset tracking to move products with robotic precision to ensure orders get to customers faster.

Check for Scalability and Integration

You surely don’t want to deal with a tool that refuses to be friendly with others. Thus, choose a solution that integrates smoothly with our existing ERP, CRM, or IoT platforms. You must also remember that your business is not static; neither are your asset monitoring solutions! What worked for a fleet of 7 delivery vans will not be enough when you expand it to 100. One such example is that of Tesla. They not only build electric cars, but also systems where software updates keep improving them.

Evaluate Cost vs. ROI

Asset monitoring will cost you money, but not having it would cost at least 10 times as much. If you plan to waste thousands of dollars, you may not get involved in the discussion. However, to prevent such disasters, list your requirements and talk to asset management providers. Not only will you save money, but you will also enjoy top-notch asset performance at all times.

User-Friendliness and Customer Support

No one wants to deal with an asset monitoring system that requires Ph.D.-level expertise. Organizational productivity will suffer if your employees need weeks of training to understand the dashboard. Thus, it is best to opt for solutions that offer solid customer support, intuitive interfaces, and transparent reporting. Otherwise, your plight will be the same as that of global airlines, which had to bow down to IT failures. This means even the most expensive tech is useless if no one can use it.

Cybersecurity and Data Protection

Your assets are more precious than gold and diamonds combined. If your monitoring system is vulnerable, cybercriminals can sell your inventory, reroute your shipments, or even worse, permanently shut down your establishment. Thus, it is best to partner with solutions that offer top-notch compliance, strong encryption, and multi-factor authentication. You can ignore this suggestion if you wish to witness a ransomware attack asking for Bitcoins!

Further Reading

Future Trends in Asset Monitoring

If asset monitoring were compared with a superhero, it would be Iron Man. And, why do we say that? Iron Man constantly evolves with better technology, has fewer malfunctions, and has more innovative systems. Modern businesses track their assets, predict failures, and use AI to make asset management smoother than Netflix’s recommendation algorithm. Let’s see what the future holds for businesses.

AI and Predictive Analytics

Yes, machines know a lot more than we do. Gone are the days when using GPS trackers and barcodes was considered a technological marvel. Businesses that innovate with AI and predictive analytics will continue their legacy. Not only will they be proactive, but they will also prevent many disasters from happening. One such example is that of Rolls-Royce. The automotive giant uses AI-powered predictive maintenance to alert airlines, massively reducing downtime. AI is no less than a psychic mechanic who fixes your car before it can break down.

IoT Expansion

What would happen if your assets started talking to each other? Soon, everything from coffee machines to forklifts will have sensors telling their internal state in real time. With over 75 billion IoT devices expected by 2025, you will be left looking at your competitors if you are not adapting. Don’t let that happen to your business!

5G and Edge Computing

What if you get a traffic report after you have hit the jam? Delays are not suitable for asset health. Luckily, with 5G and edge computing, tracking assets has become lightning-fast, and this way, you can get real-time insights and say goodbye to slow processing. This is why Verizon and AT&T are rolling out 5 G-powered asset monitoring for logistics and supply chain businesses. Moreover, industrial enterprises will use edge computing to process data faster and upgrade before your competitors can do so!

Drones and Robotics

Tell us something. Do you love walking around and manually assessing assets? If you are fine doing that, it’s okay. Otherwise, if that’s not something that fits you right now, you will love what the future holds. Drones and robots handling asset monitoring would be the new normal. Oil and gas companies like BP have already jumped on the train and cut their inspection costs by 50%. At the same time, Amazon has cut its processing times and made its operations much faster. Soon, all industries will follow suit. As let’s be honest, drones are much more efficient and don’t even complain like humans.

Sustainability and Green Asset Monitoring

Yes, saving the planet is a responsible and trending initiative (for many decades). Consumer demand and regulations have pushed businesses to be more environmentally friendly. In the future, asset monitoring systems will achieve zero carbon footprints, minimize waste, and optimize waste. The efforts started a long time ago. The popular logistics company DHL uses AI-powered route optimization to save 50,000 metric tons of CO2 annually. You can expect more businesses to leverage asset tracking to boost efficiency and meet sustainability goals.

BuzzClan: Your Asset Monitoring Solution!

Choosing BuzzClan as your asset solution is like hiring a personal trainer for your business. Our team of experts whips your asset management into shape with cutting-edge tech, strategic insights, and seamless execution, ensuring your resources work smarter, not harder. We guarantee the process is top-notch and all your demands are fulfilled. A detailed roadmap, communication that makes the toughest challenges more effortless, and the best tools await you. So, skip the chaos and let BuzzClan handle your assets. Here is what our expert Abhi Garg (CRO—BuzzClan) says.

“The evolution from basic asset tracking to advanced monitoring represents one of the most significant operational transformations in enterprise IT. Modern asset monitoring combines real-time telemetry with predictive analytics to identify and anticipate issues. In our work with major utilities and financial institutions, implementing these advanced monitoring practices has reduced mean time to resolution by over 60% while providing crucial insights for strategic capacity planning.”

Here are some reasons to partner with us.

- Automated compliance and monitoring

- Real-time cost monitoring

- Predictive scaling capabilities

- ROI-focused implementation

- Seamless application modernization

- Industry-specific compliance expertise

- Reduce deployment time by up to 60%

Final Words: Monitor or Suffer

With the business world changing faster than the blink of an eye, ignoring asset monitoring is equivalent to driving a car blindfolded on a hilly terrain, waiting for the vehicle to fall off the cliff. Tesla’s real-time battery monitoring predicts failures much before they happen. Another successful example is Amazon, which has robots as its friends and tracks inventory with near-perfect accuracy.

By following the best practices, taking care of security, and investing in the right tools and technologies, you protect your assets and prepare them to face all storms. Remember, asset monitoring is not about tracking things; it is about saving money, eliminating competition in thin air, staying ahead, and optimizing operations. So, whether you are handling a manufacturing plant, healthcare equipment, or a data center, remember: if you can manage it, you can monetize it! If you think you can get away without good monitoring techniques and strategies, your competitors will outlast you. It is time to hop on the train and take accelerated action!

FAQs

Get In Touch